Big Bang! Poof, the universe has come to life! Within a few minutes of the Big Bang, a mineral known as lithium was created. It was one of the first three chemical elements to form in the universe, along with hydrogen and helium. Back then it was found in earth’s salt flats and rock formations. Now, 13.8 billion years later, it’s found in everything from our iPhones to our electric vehicles to even our blood!

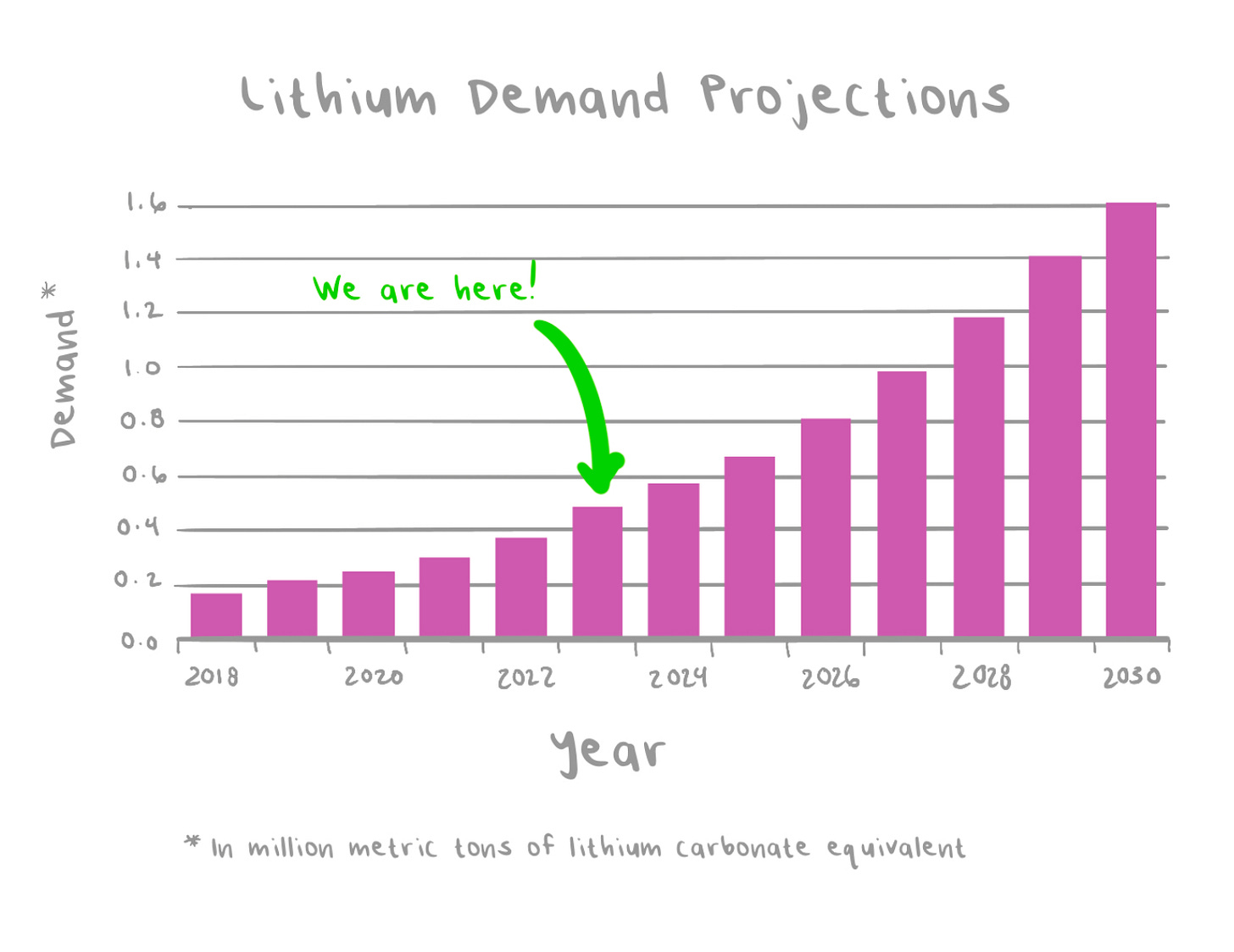

As it relates to climate change, lithium is the core component of batteries - it’s a rare mineral that packs its punch. Lithium is a reactive and lightweight material that can store large amounts of energy in a small space – thus making it the ideal material for use in batteries. Most batteries, from your energizer bunny to your iPhone to your electric vehicle to your battery storage unit for wind and solar, all use lithium as their main component. As the world embarks on a massive energy transition to decarbonize our economies, lithium demand is expected to increase 761% from 2020 to 2030!

Needless to say, everyone wants in on this white gold! The geopolitics of lithium resources is a much longer conversation – we’ll save that for another post. Today, we wanted to lay the groundwork and give you a sense of where all this lithium lives, at least currently. Our friends down under in Australia have the greatest level of discovered reserves and supply countries across Europe and South Asia. Over half of the global lithium reserves are in the lithium triangle in South America, namely Chile, Argentina, and Brazil and there is more development underway in Bolivia (financed by none other than China). And the manufacturing powerhouse of the world, China leads the pack for actual production, with ~75% of the world’s batteries coming from the superpower. If you really want to dig in, take a look at this incredible tool from the World Bank that helps you map lithium supply chains. Energy independence, in all its forms, has taken a forefront in the global political zeitgeist and countries around the world are in a race to find it!

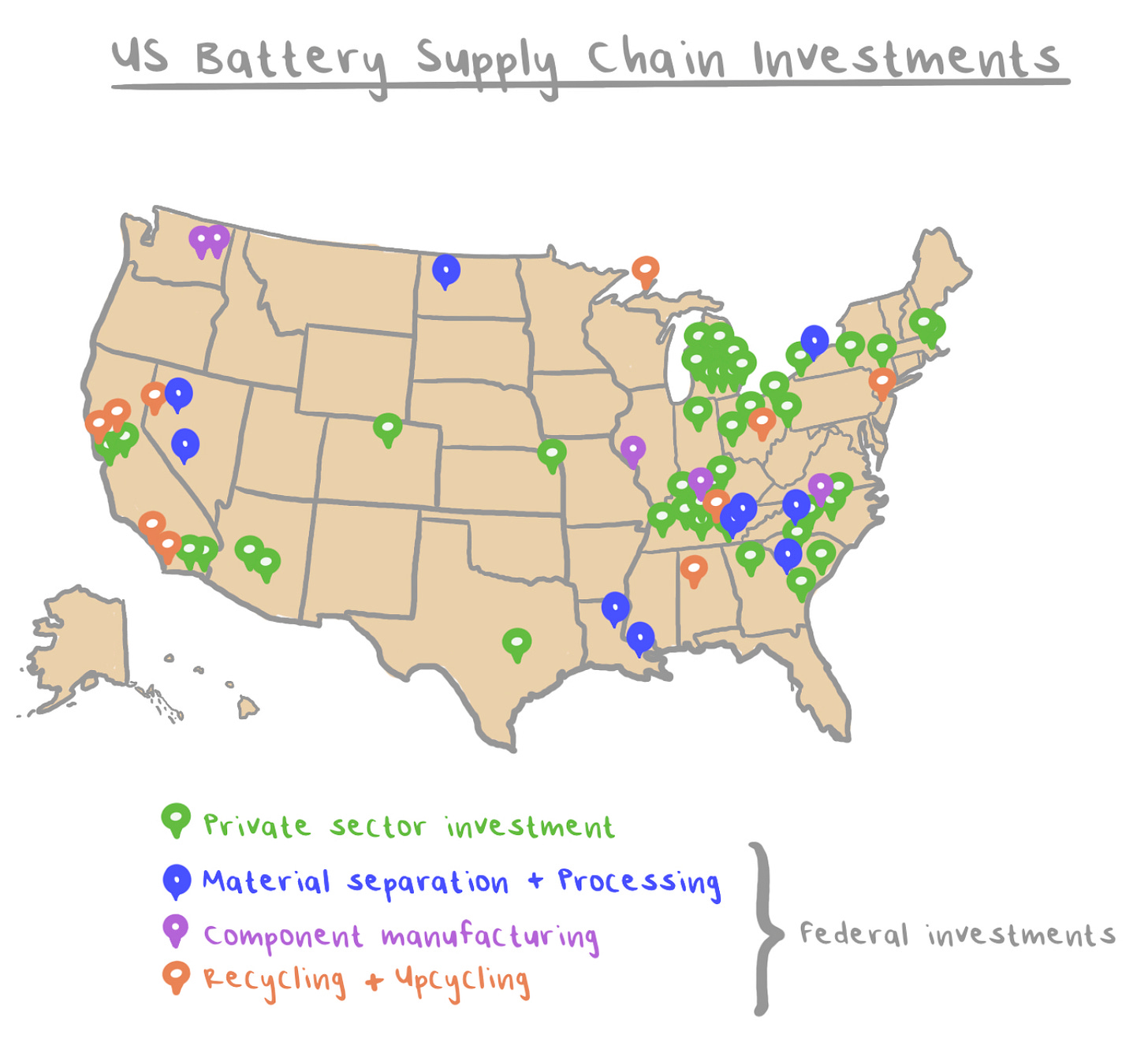

We can go on and on — but wanted to focus on how the battery supply chain is going to fundamentally shape our physical spaces and industries over the coming decades. Though we usually don't focus on funding rounds, we're diverging a bit from our usual format this week to show you where the money is flowing! We think this will be an early glimpse into what the Climate Industrialism hubs of tomorrow will look like — and where they'll be.

And before we dive in, a special shout-out to our many twitter friends, mining friends, and fellow Substack writing friends, all of whom have been our go-to’s for all things related to batteries. Give them a read!

Battery materials: So, where does all this stuff come from?

India, one of the world’s largest energy consumers, has struck a gold mine. Or more accurately, a white gold mine. The federal government announced it found 5.9 million tons of lithium reserves in the northern Jammu and Kashmir region, in the eco-sensitive Himalayan range near the border of both Pakistan and China. With a heavy reliance on coal for its energy needs, India aims to create 50% of its electricity from non-fossil sources by 2030 - an area where lithium energy storage will play a crucial role.

For years, Nevada has been starting to position itself as the center of the domestic lithium supply chain - a place where companies can extract, recycle, and market this white gold. The state’s Division of Minerals has tracked about 35,000 (!) claims related to lithium, from established firms to startups to speculators scouting the land. GM is backing the Thacker Pass mine near Winnemucca with a $650 million investment and even the US government is making its mark with a $700 million loan for the Rhyolite Ridge lithium-boron project near Tonopah. Seriously, white gold is the new blackjack here!

Startups are taking notice! Lilac Solutions based in Oakland, California has raised over $150 million from investors like Prime Coalition and Lowercarbon Capital to develop a technology that lowers the amount of land and water needed to mine lithium from continental brines. Their ion-exchange beads absorb lithium as they flow through big tanks that hold brine, and then flush the beads with hydrochloric acid to produce lithium chloride – all of which ends up in battery cells for electric vehicles!

Or! What if we didn’t have to mine lithium in the first place, and instead developed solutions with co-benefits? Well, our friend Lacey Reddix at Olokun Minerals (based in Los Angeles, CA and Norfolk, VA) is doing just that. Olokun recovers minerals like lithium, magnesium, calcium, etc. from the brine waste leftover from desalination processes, and sells those minerals to industrial buyers. This helps make desalination a more cost-effective and more environmentally safe method to generate clean water, and provides new life to materials that are otherwise wasted.

Battery manufacturing: Battery startups recharging their coffers to go big!

Chicago based NanoGraf just raised a $65 million Series B round to make silicon-anodes for lithium-ion batteries. This is on top of a $10 million contract from the US government to build its first manufacturing facility in the Midwest. NanoGraf’s 18650 cell has 20% higher energy density than the industry’s leading cells today — think of them powering the next energizer bunny to keep going and going and going…!

Zero-waste battery production is coming our way! Quino Energy raised $4.55 million last week to develop water-based flow batteries that store electrical energy in organic molecules called quinones. They are testing these products at an onsite microgrid at the company’s lab in San Leandro, California – collecting real-world data that could transform the grid energy storage industry.

Long-duration energy storage solutions are all the rage, and VFlowTech based in Singapore is leading the charge (pun intended!). They just raised a $10 million Series A to create a modular vanadium redox flow battery energy storage system that can be deployed anywhere – from residential buildings to commercial wind farms. Since the technology can operate in temperatures from -10 to 55 degrees Celsius, it really can be deployed anywhere. With a 25-year lifespan, and a levelized cost of storage as low as $0.10/kWh, we can’t wait to get our hands on these cubes!

All these are cool new manufacturing techniques, but how can you get the most juice out of these battery systems once they're up and running? Liminal combines ultrasound technology with machine learning to deliver advanced insights for auto manufacturers, particularly as it relates to the batteries in their cars. They just raised $17.5 million in Series A2 funding led by climate tech fund ArcTern Ventures. The technology can discover flaws while the batteries are being produced and flag defects to the manufacturer, saving them from costly recalls that have plagued the industry!

Battery recycling: The circle of (battery) life!

Pursuant to our mantra at Parachute, policy-makers are market-makers in this industry! In 2024, the EU is instituting a series of new regulations that require EV manufacturers to recycle batteries at the end of their lifespan. German based battery recycling startup Cylib couldn’t be happier, nor could their investors led by World Fund, who’ve collectively plowed in $12.6 million to help the company build a new recycling factory. Three cheers for the mobility sector running on electrified, regenerative systems!

Ecobat, the world’s largest lithium ion recycler, has its eyes set on the US! Already operating 12 sites in Europe and South Africa, the company has 65,000 battery collection points and a massive operation. Their new facility in Casa Grande, Arizona will produce 10,000 tons of recycled materials every year — only to grow as we electrify everything!

The Infrastructure Bill is doling out cash left and right to close the loop! The Department of Energy gave Cirba Solutions $75 million to open a 150,000 sq ft facility in Lancaster, Ohio (part of the battery belt!). They’ll be able to produce enough battery-grade critical minerals to power 200,000 EVs every year! Bonus points: this is on top of a new facility already in the works in Eloy, Arizona!

And the biggest of them all: Redwood Materials has secured a massive $2 billion loan from the Department of Energy to build a new 600-acre battery plant outside of Charleston, South Carolina. The new facility will create 1,500 jobs and produce 100 GWh of cathode and anode components every year. Not to mention, they’re already on the ball — breaking down scrap EV batteries from Ford, Toyota, Nissan, Specialized, Amazon, Lyft, and others.

Finally, friendly reminder that all of the companies that we highlight here are cataloged in our database: Doom Diligence! You can see a sneak peek of it below, and paid subscribers get full access. Now that we’ve finished up our most recent research trip, you’ll be seeing a lot more updates to that database!

Paid subscribers, your Doom Diligence access is down here!

Keep reading with a 7-day free trial

Subscribe to Parachute to keep reading this post and get 7 days of free access to the full post archives.